|

|

Product Description

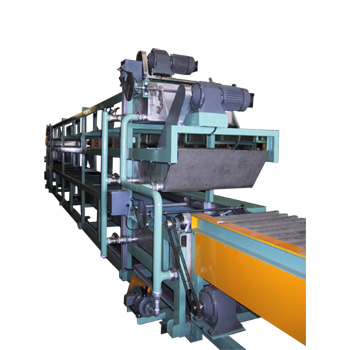

Overall Machine

- Length: 22.8m

- Tallest point of Machine: 2.2m (The highest point of the machine is the cooling conveyer drive motor)

- Tread conveyer maximum width: 700mm

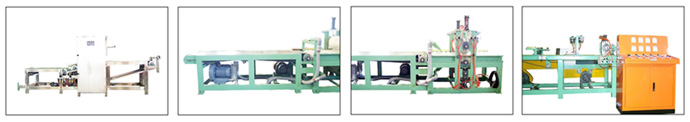

Tread rubber extrusion section with word and line printer

- Overall section length: 4.3m

- Tread rubber extrusion section with mark and color line printer

- Tread rubber extrusion section with date of manufacture printer

Tread Rubber Cooling Conveyer

- Overall cooler length: 10.2m (Standard)

- Overall length of cooler and conveyer: 30 m (standard)

- Three level stainless steel cooling water trough

- Cooling water trough with removable conveyor belt imported from Holland

- Cooling conveyer powered by 3 phase 2 HP motor

- Cooling conveyer with speed and placement sensors(Dancer Rollers)

Tread Cutting Skiver Section

- Overall section length: 4.3m

- Tread Cutting Skiver Section constructed from stainless steel

- Tread Cutting Skiver conveyer powered by 3Hp servo motor

- Tread Cutting Skiver Section adopts Japanese brand THK guide ways

- Tread Cutting Skiver Section employs German brand FESTO shaftless pneumatic pressure cylinder

- Tread Cutting Skiver powered by 3 HP ?4 phase motor

- Tread Cutting Skiver equipped with cut angle adjustment device

- Tread Cutting Skiver provided with spare cutting blade

Tread Rubber Dryer

- Overall machine length: 3.8m

- Tread rubber dryer fitted with four highly absorbent sponge rollers

- Tread rubber dryer equipped with two high force blowers each with a 2 HP motor (wind knife to use)

- Tread rubber dryer employs sponge rollers and air blowers to rid tread of any residual moisture.

This is the detailed information for Tread Process Line. The information includes model, name, description and specification for Tread Process Line. Related Keywords : Tread Process Line, Tread Making Equipment, Tire Machine, Tire Tread Making Equipment, Tire Tread Making Machine, Tire Tread Process Line.